Rumored Buzz on Programmable logic controllers (PLCs) - Eaton

In today's society, we depend on automated equipment to carry out numerous of our most important industrial processes, from generating electricity to weaving material. Another Point of View has allowed us to scale brand-new heights of production and innovation. But our present level of automation would not be possible without a critical development called the programmable reasoning controller (PLC).

Our beginner's guide to PLCs will present you to the fundamentals of PLCs, talk about why these controllers are so essential and supply a fast primer on how they work. We'll also talk about a few of Polycase's best electrical enclosures for PLCs that will secure your most vital control systems.

Fundamentally, a PLC's task is to control a system's functions utilizing the internal logic configured into it. Companies worldwide usage PLCs to automate their most essential processes. A PLC takes in inputs, whether from automated data catch points or from human input points such as switches or buttons.

Examine This Report on Programmable Logic Controllers - UCSD Extension

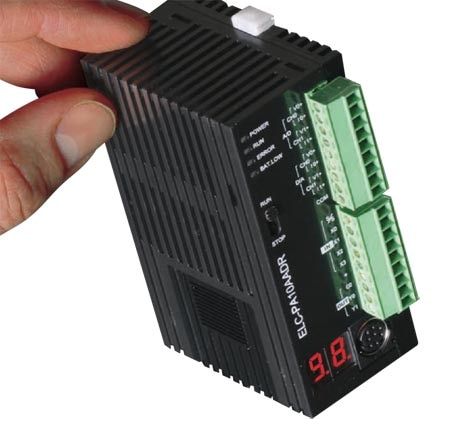

A PLC's outputs can manage a substantial range of equipment, consisting of motors, solenoid valves, lights, switchgear, safety shut-offs and lots of others. The physical location of PLCs can vary widely from one system to another. Usually, nevertheless, PLCs are situated in the basic area of the systems they operate, and they're generally safeguarded by a surface area install electrical box.

PLCs largely replaced the manual relay-based control systems that prevailed in older commercial centers. Relay systems are intricate and prone to failure and, in the 1960s, the inventor Richard Morley presented the very first PLCs as an alternative. Manufacturers rapidly understood the potential of PLCs and started integrating them into their work processes.

In reality, they're still the most used industrial control innovation worldwide. The ability to deal with PLCs is a required skill for various occupations, from the engineers developing the system to the electrical service technicians keeping it. PLCs have actually been a standard component of industrial machinery design for numerous decades.

Programmable Logic Controllers (PLC) - Panasonic Industrial Things To Know Before You Get This

Their shows languages are basic in comparison to other industrial control systems, which makes PLCs great for businesses that wish to decrease complexity and expenses. PLCs are a fully grown innovation with years of scr